Becoming the digital company

Our client is one of America's largest manufacturers and distributors of commercial hardware products such as doors, door frames and access control devices with 40+ manufacturing, distribution, and corporate facilities across the nation.

Between massively distributed operations and multiple acquisitions, the client was facing a daunting challenge of integrating, standardizing, and automating their fragmented, ad-hoc, and often paper-based processes.

The client’s CIO reached out to Rapidops with a vision and initial strategy to unlock potential opportunities to improve operational efficiencies, monetize digital innovations, and deliver seamless customer experiences.

Opening the ‘digital’ doors, one at a time

The vision was clear, and the executive team was committed to delivering on it. However, there wasn’t enough clarity on execution and priorities. This was a multi-year initiative. When we got started, the client had identified a few ideas, but they did not have a clear roadmap, scope, or delivery strategy due to the lack of time and resources. Having done a similar journey before, we knew that we had to work closely with the key stakeholders and decision-makers to understand their vision, goals, and priorities.

As always, we wanted to move fast and deliver the real product. We jumpstarted a two-week design sprint with CIO’s team and executive teams with direct support from CIO. We asked many questions and listened carefully to understand their business and critical needs. Together we prepared a prioritized roadmap and also hit the ground running with the key opportunities.

Our product team went deep into their manufacturing, distribution, and business processes. The engineers explored their legacy and IT ecosystem. Our design team came up with a beautiful prototype for the first initiative - all in the first 2 weeks.

The executive team loved the prototype and we had a green light to go ahead and deliver it!

Breaking barriers to better business

The client was using an industry-specific ERP system for their core business, a desktop-based solution with intranet-only access - no integration points or documentation. In addition, most of the newly acquired companies were using their own isolated ERP systems with similar limitations. To build any digital solution, we had to make these systems talk to each other. This was the first and by far the biggest technical challenge.

We analyzed the client’s enterprise systems, architectures, and technical implementations to engineer a platform that orchestrated and integrated their disjointed business and data systems. This removed the roadblocks to reshape the client’s business.

Integration & Automation Platform

As the client’s business was expanding and growing rapidly, we had to make sure that new platforms and apps can evolve, adapt, and scale to meet the changing needs. Our team designed and engineered the platform that orchestrated and integrated multiple systems and offered a reusable API framework to develop automation.

The API-driven platform allowed us to be extremely lean and agile in delivering apps and automation in a matter of days - reducing time to market and costs. The platform is becoming the strategic digital asset that keeps growing as we continue to digitize our client’s key business processes.

Crafting a consistent experience for all apps

When we started the initiative, the client did not have a design system for developing digital apps.

Our design team went deep into the client’s branding and user needs to build a system -- a well-crafted collection of reusable UX/UI components and standards. It enabled designers and engineers to ship beautiful & consistent products in a matter of days. Anytime we had to update UX/UI, we only had to change one component in the design system, and all apps got the new update automatically. Feels like magic!

Most of the new apps were going to be used by the employees across all locations, and a consistent experience improved productivity, adoption and resulted in fewer user errors.

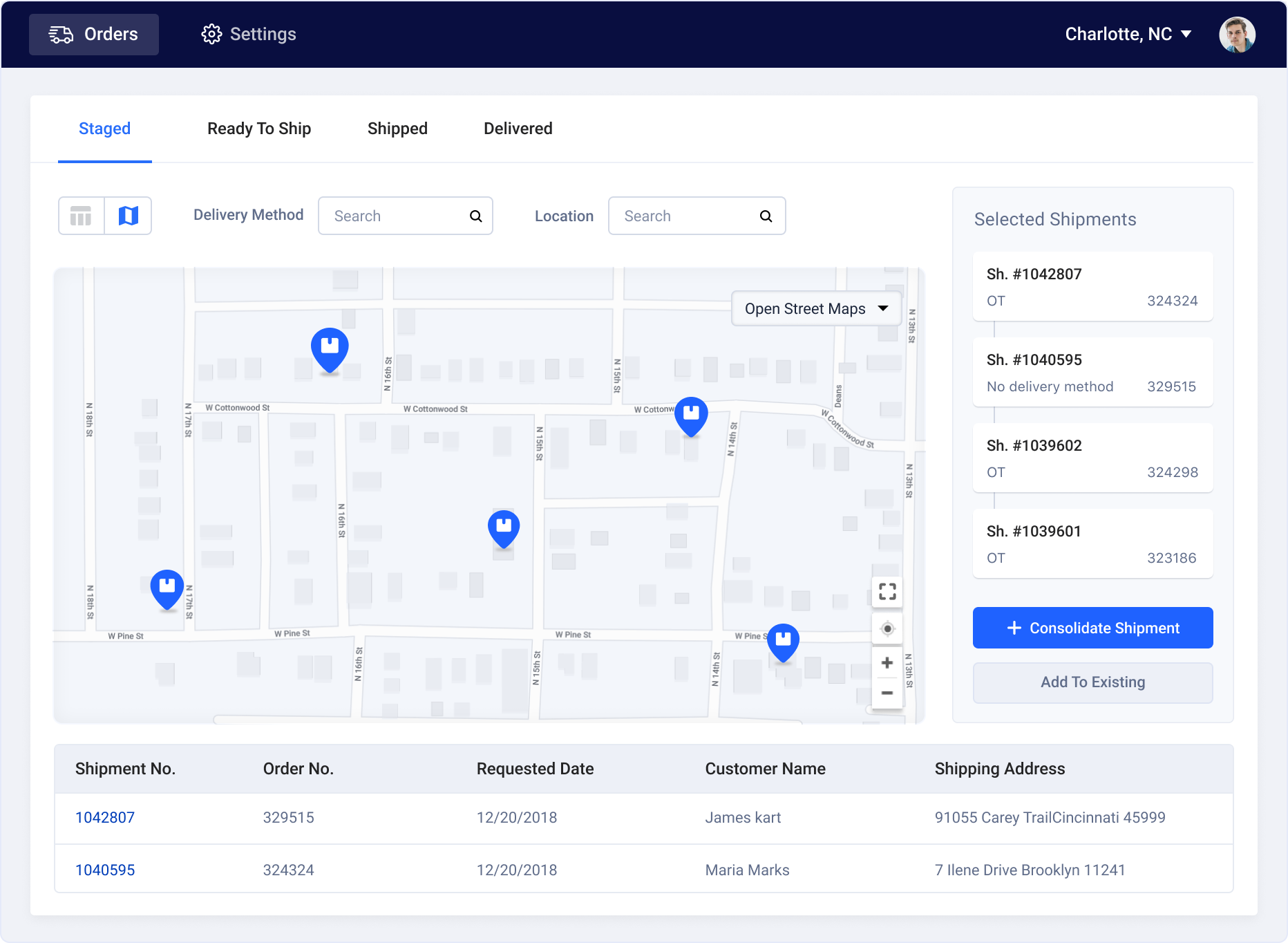

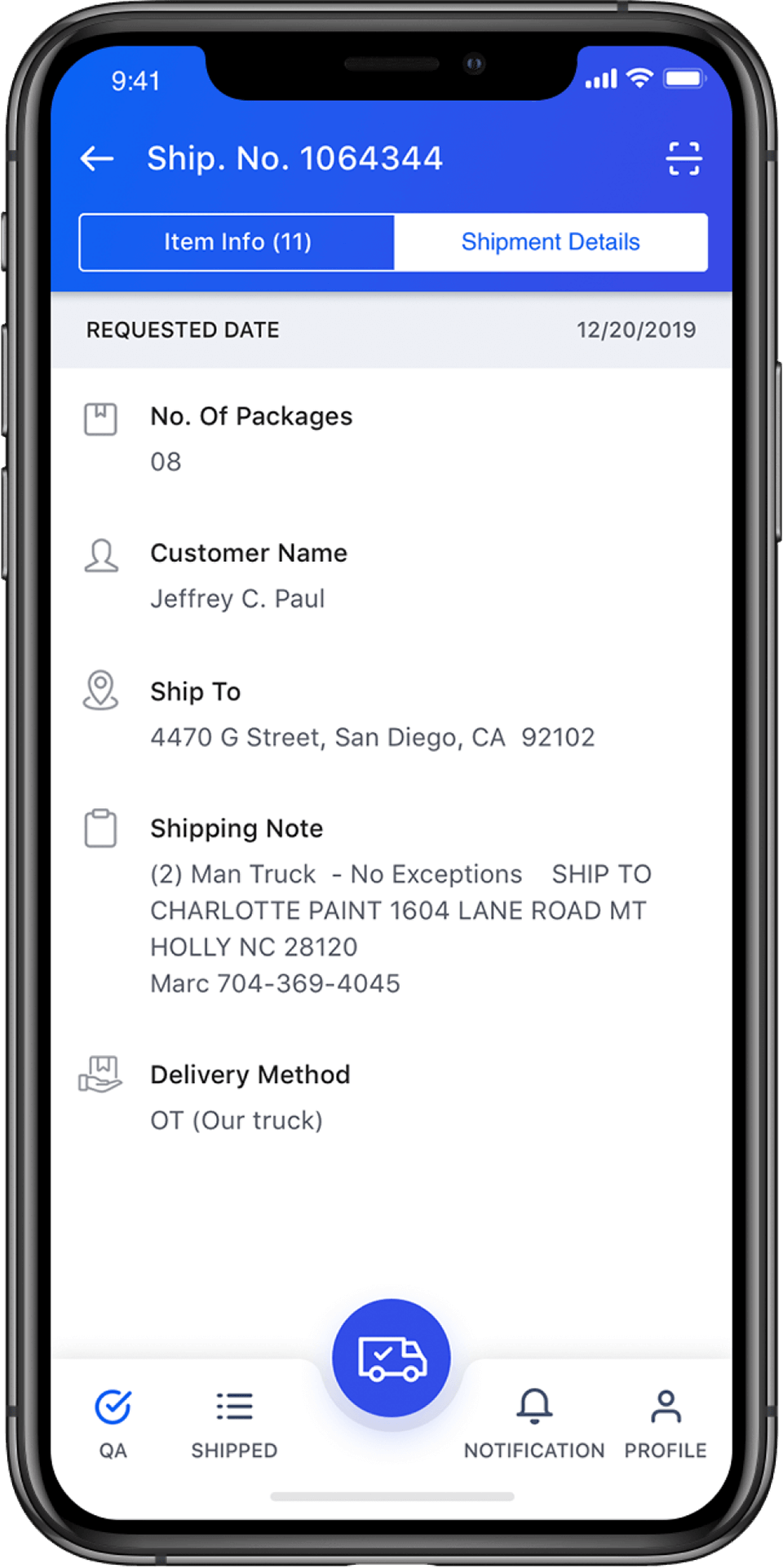

Automating the Last-Mile Delivery

The client does the last-mile delivery of finished goods to their customers from their warehouses. The current process was complex and paper-based, involving multiple steps, people, and locations. It often resulted in increased delivery times, missed deliveries, higher costs, and bad customer experiences.

We designed and developed an end-to-end last-mile delivery platform that digitized the

entire process for delivery managers, warehouse staff, and fleet drivers in just 60 days.

The product enabled these key business features:

- Order processing, grouping & shipment design

- Real-time tracking & alerting of all shipments at each stage

- Smart delivery cost, SLA and route optimization

- Shipment loading, dispatch and management

- Multiple shipping methods - fleet or third party (Like FedEx)

- Capture digital proof of delivery & feedback

- Real-time monitoring & planning app for delivery managers

- Delivery app for drivers with offline mode for remote areas

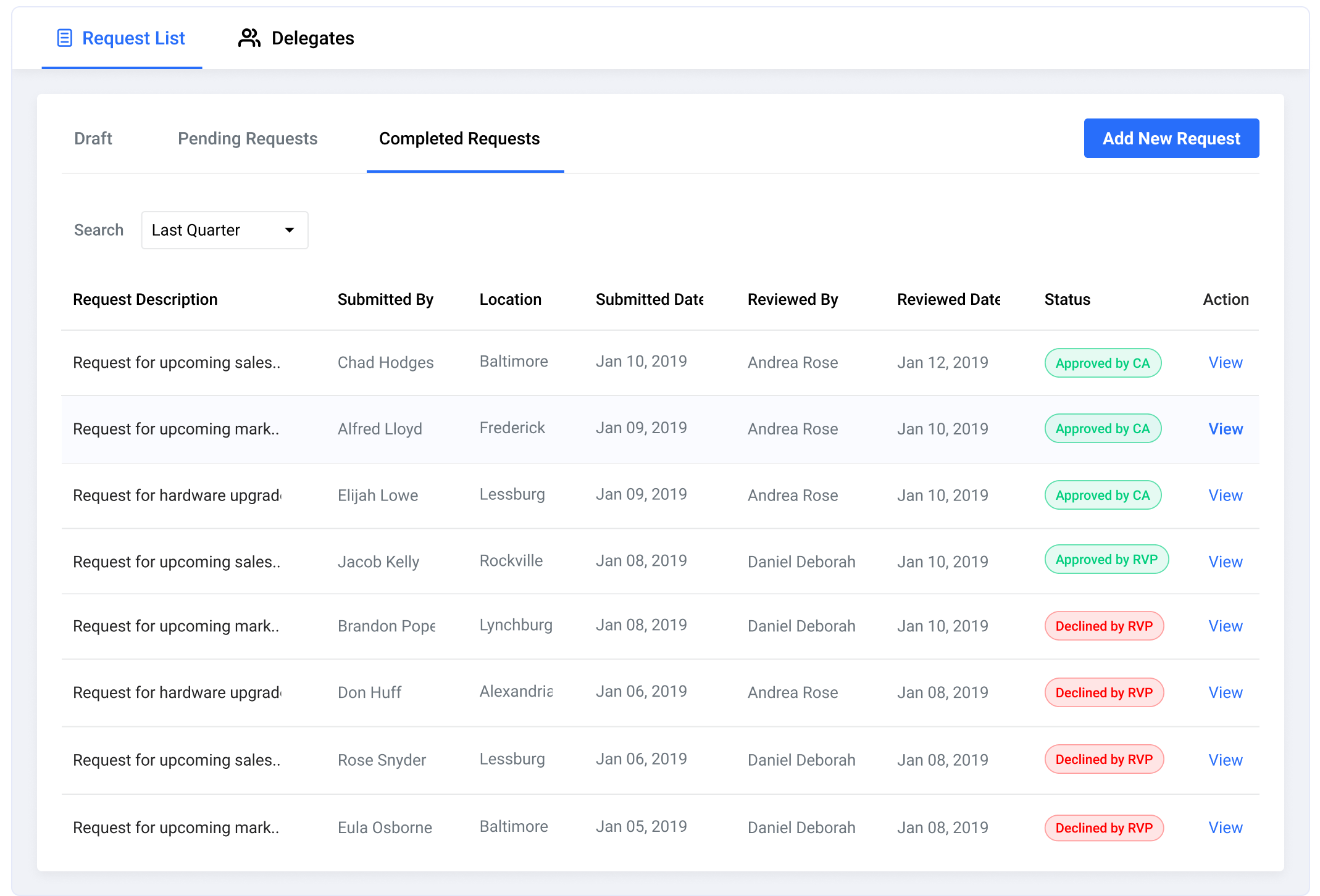

Digitizing Procurement Approvals

The client was using the existing intranet-based system to get approvals for procuring materials and supplies. Purchase requests often got stuck in the approval process and caused significant delays in procuring required raw materials to deliver the client projects. The client wanted us to digitize the entire process and provide transparency, efficiency, and accountability for all purchase approvals.

We found that the current process was manual and relied on emails and phones. People tend to forget to prioritize these requests, and the pain multiplied when the requests had to escalate for more senior approvals. We delivered a flexible workflow automation app that enabled employees to raise, review, and approve purchase orders across multiple locations and organizational hierarchies. The approvers get notified of requests and can get all details they need to make quick decisions.

“The automated procurement system helped the client streamline their entire process, eliminate manual work, and increase operational efficiency. The approval time got slashed in half, and there was total transparency across the entire business.”

Digitize Proposal & Discount Approvals

Similar to procurement processes, the client’s sales team was caught up in delays when they needed to get discount approvals for the big sales opportunities. Rapidops was able to digitize the entire process with the workflow automation app that we built for procurement approvals in a matter of days.

“The new process automated discount approvals and shortened the approval cycle that enables sales teams not to get stuck in waiting loop and offer approved discounts to customers in record time.”

Automating the operational processes

As a large distributed enterprise, the client has many manual and paper-based processes resulting in delays and lost productivity. We prioritized and started automating key business processes one by one on the new platform.

Accounts Payable

With thousands of vendors and partners, the accounting team had to dig through orders, terms, and discounts to dispatch the payments manually. The process was fragmented and wasted so many man-hours every month.

In 30 days, we automated the entire payments process with an intelligent payments engine. The engine integrated with their ERP, payment provider, and vendor information systems. All payments are automatically validated, processed, and dispatched to vendors directly - no human touch is required.

Resource Management

The client was using multiple disconnected systems to manage their active projects, job workers, and timesheets. It prevented them from gaining essential insights about the project, workers, and budgets.

We integrated their ERP and timesheet management systems to identify the resource allocation and labor expenses. In addition, we enabled them to unlock the key business intelligence using Microsoft PowerBI integration.

Delivering ROI and gearing up for growth

Together with the client team, we have built a digital foundation that will help shape the future of their business. With automation, digitization, and integration of operational processes, the client has realized cost savings, operational efficiencies, and improved customer experiences. With the real ROI on the table, there is a significant cultural shift to build the digital-first agile business, and we continue to help them transform and grow.

Over the last 20 years, I've worked with many firms, onshore and offshore, and the team at Rapidops is the best that I have ever worked with. Rapidops’ team’s ability to understand the vision and translate it into digital products is mind-blowing.